AlNio is an term referring to a series of permanent magnet alloys which in addition to iron are composed primarily of aluminium (Al), nickel (Ni) and cobalt (Co). The development of alnico began in 1931, when T. Mishima in Japan discovered that an alloy of iron, nickel, and aluminum had a much higher coercivity than the best steel magnets of the time. The composition of alnico alloys is typically 8–12% Al, 15–26% Ni, 5–24% Co, up to 6% Cu, up to 1% Ti, and the balance is Fe.

AlNiCo magnet is the first permanent magnet material developed. It is an alloy composed of aluminum, nickel, cobalt, iron, and other trace metals. Initially designed for meters and instruments, AlNiCo are well known for excellent temperature stability, high residual induction, and relatively high magnetic energy.

The temperature stability of Alnico magnets, and the fact that they can be used in very high temperatures, up to 500℃, which make them indispensable in certain applications.

In the AlNiCo alloys family, isotropic and anisotropic magnets with different properties can be produced with different composition and production processes.

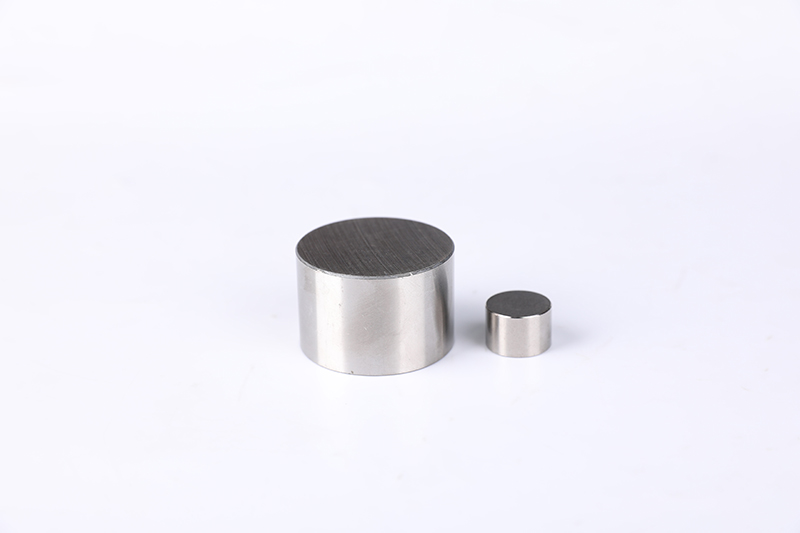

AlNiCo can be divided to cast AlNiCo and sintered AlNiCo. When compared with cast AlNiCo, sintered AlNiCo perform with lower magnetic properties but better mechanical properties. AlNiCo are brittle and hard, not suitable for traditional maching processes except grinding processing.

E-mail: info@tedamag.com

Add: Yard 2, Yijin North Street, Daxing District, Beijing, China.